107 | Top Food Safety Non-Conformances and How to Avoid Them

Plus big business and food fraud + chemical hazards in soy foods and supplements

This is The Rotten Apple, an inside view of food integrity for professionals, policy-makers and purveyors. Subscribe for weekly insights, latest news and emerging trends in food safety, food authenticity and sustainable supply chains.

Celebrating Food Loss Awareness Day

Food safety non-conformances and how to avoid them

Food fraud: big business versus small businesses

Chemical hazards in soy-based foods

Food Safety News and Resources

Food Fraud News and Recent Incidents

🎧 Listen Now (for paying subscribers) 🎧

Hi,

Welcome to The Rotten Apple and Happy Food Loss Awareness Day. Thank you to everyone who has renewed their subscriptions lately, your ongoing support fills me with joy 😊.

In this week’s issue, you’ll get help with common food safety non-conformances, learn which sized business is riskier for food fraud and discover new chemical hazards in soy-based foods.

There is a heap of food safety news this week, including news from Africa, Asia and Australia - a few unusual food-pathogen combinations too. Plus three free webinars to stimulate your synapses.

As always, food fraud news is at the end for paying subscribers (who are excellent humans!). This week we’ve got good survey results for fish fraud in the UK; bad results for meat; horrible-sounding fake wine made with ethanol, dye and grape flavour (yuk), plus much more.

If you like this newsletter, please take a moment to tell your friends and colleagues about it. Your shares make a genuine contribution to the continued viability of this publication (thank you.)

Have a fabulous, waste-aware week.

Karen

International Day of Food Loss/Waste Awareness, 29th Sept

How to celebrate:

Join other food professionals at a global event including two online courses hosted by the FAO

Discover how to quantify food loss and waste

Top Food Safety Non-Conformances and How to Avoid Them

During a food safety audit, auditors award non-conformances when food businesses don’t comply with the requirements of the standard to which they are being audited. Non-conformances are graded according to how important they are to food safety outcomes.

If a food site gets too many non-conformances it can lose its food safety certification, which impacts its ability to sell its products. More importantly, a site with many non-conformances is at risk of shipping unsafe food, which could make people sick and lead to expensive recalls.

Top non-conformances

The non-conformances listed in this post are sourced from two of the most prestigious standards owners: BRCGS (British Retail Consortium Global Safety) and SQFI (Safe Food Quality Institute). Their standards are used to certify the food safety systems at tens of thousands of sites worldwide.

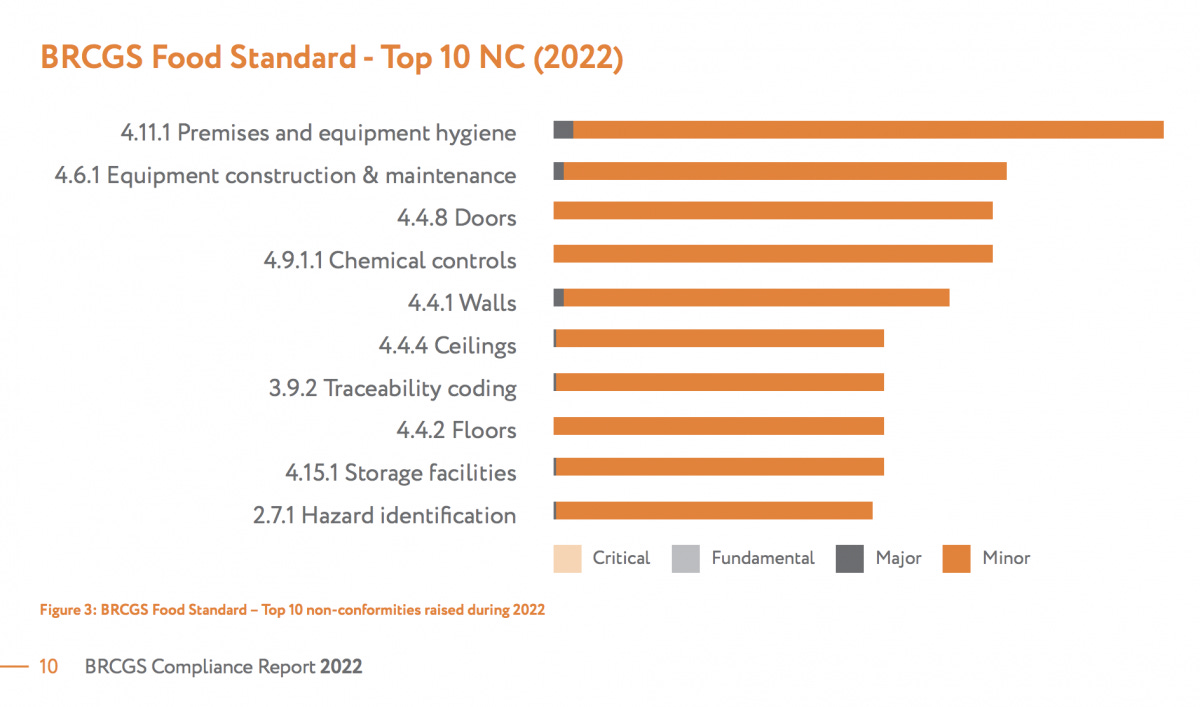

The most prevalent non-conformances change over time, often reflecting changes to standards and auditing expectations. For example, BRCGS renewed their focus on physical site visits following the easing of the Covid pandemic, and this is reflected in their top non-conformances for 2022, of which more than half were related to the condition of physical attributes of facilities, equipment and fixtures, as opposed to systems, personnel or documentation failures.

The SQFI also reported a “distinct change in the number and type of non-conformances” following their transition to a new edition of their main food safety standard in 2022.

Top areas of non-conformance, combined for audits to BRCGS and SQF food safety standards, are discussed in detail in this post:

Premises and equipment;

Pest prevention activities;

The food safety plan;

Chemical controls;

Traceability;

Storage procedures;

Management reviews and internal audits.

Premises and equipment

Problems with the hygiene of premises and equipment are the most common reason for non-conformances for food businesses audited to both the BRCGS Food Standard and the SQF Food Quality/Safety Codes.

The SQF Institute reports that cleaning, sanitation and maintenance of equipment, buildings, floors, ceilings, walls, doors and junctions were notable sources of non-conformances in 2022. For businesses audited to the BRCGS Food Standard, six of the top ten non-conformances related to the construction, design or sanitation of premises and equipment, such as walls, ceilings, floors, and food processing equipment. Non-conformances for Clause 4.11.1 Premises and equipment hygiene were the most numerous types of non-conformance issued in 2022.

Hygiene relates not just to cleanliness but also to the design, construction and maintenance of fixtures, fittings and equipment. These must be both clean at the time of the audit and designed and constructed to be easy to keep clean.

For example, BRCGS Food 4.4.1 Walls states that “Walls shall be finished and maintained to prevent the accumulation of dirt, minimise condensation and mould growth, and facilitate cleaning.” and 4.4.2 Floors states that floors “shall be impervious, be maintained in good repair and facilitate cleaning.”

Auditors award non-conformances for loose wall or floor tiles, broken tiles, cracked surfaces, flaking paint, unsealed joints, unsealeded (bare) concrete and floors with poor gradients which allow water to form pools instead of draining away.

Areas that are not kept clean or are difficult to clean have resulted in many deadly outbreaks of foodborne illness. One such outbreak, caused by Listeria-contaminated cantaloupes, was the USA’s deadliest outbreak since 1924, killing 30 people.

The cantaloupes were contaminated by processing equipment which was neither clean nor easily cleanable when the FDA investigated. The equipment’s rollers “had an accumulation of dirt and needed to be cleaned, [and] the poles used to push cantaloupes on the packing table had balls of [redacted] on the ends that are not cleanable” (FDA Inspection report). Clean and cleanable equipment could have prevented the 30 deaths in this outbreak.

Pest prevention activities

For as long as I have been in food safety, pest-prevention systems have been a major source of non-conformances. They did not appear as a stand-alone item in last year’s BRCGS list, but it’s worth noting that the third most frequently awarded BRCGS non-conformance was for their clause about doors. And the doors clause is actually about preventing pest ingress. The SQFI reported pest prevention non-conformances were a notable trend in 2022.

The BRCGS requirements for doors are that they must be adequately pest-proof so pests can’t get into food facilities; kept closed; and/or fitted with systems to prevent pest ingress.

In my experience, many pest-related non-conformances are not the result of an actual pest infestation on the site but are more often raised because of deficiencies in pest-related documentation such as monitoring of pests and reporting of pesticide use.

The food safety plan

The food safety plan is the backbone of every food safety management system. It addresses potential hazards that could make food unsafe, and should cover every step in a food manufacturing or food handling process. The food safety plan also contains specific actions that the food business will take to ensure that all significant hazards are controlled or eliminated.

If a site’s food safety plan is not well-designed - a process that requires significant expertise - then food safety is compromised.

Both BRCGS and SQFI listed problems with food safety plans among their top non-conformances, with the area of hazard identification being the most problematic. SQFI reported that non-conformances were frequently awarded for missing hazard analyses, incomplete hazard analyses for ingredients, and misidentification of critical control points (CCPs).

Chemical controls

All food businesses should have formal processes to prevent non-food chemicals like cleaning chemicals, laboratory chemicals or pesticides from getting into food. In 2022, non-conformances in the area of chemical controls were the fourth most common type of non-conformance for BRCGS sites.

Non-conformances for chemical controls are given by auditors if a food business:

uses chemicals that are not explicitly confirmed as suitable for use in a food environment;

uses chemicals that were not selected and purchased using a formal approvals process;

does not store chemicals correctly;

does not have safety data sheets for the chemicals on-site;

keeps chemicals in unlabeled containers.

Traceability

Traceability means that all food materials in a food factory are identified down to the batch level at all times, including ingredients, partially processed products, part-used lots of ingredients and finished products. Traceability allows food businesses and regulators to accurately discover the extent of any food safety problems and remove all affected foods from the marketplace.

Auditors give non-conformances for traceability if raw materials are not labelled with batch codes; production records don’t show which batches of ingredients were used to make each lot/batch of food; work-in-progress is not properly identified with traceability codes; or if finished goods cannot be traced back to their raw ingredients.

Storage procedures

The BRCGS reports that storage issues were the ninth most common source of non-conformances for audits in 2022. The BRCGS food standard requires that food sites have robust procedures for keeping chilled and frozen products in temperature-controlled areas; segregate products to avoid cross-contamination; store food off the floor and away from walls and have protocols to avoid damaging products during handling and stacking.

Auditors look for allergen cross-contamination risks when they inspect storage areas. For example, allergen-containing ingredients and finished products should be segregated and properly sealed so that they cannot become a source of allergenic contamination.

Management reviews and internal audits

The SQFI reported that in 2022 many food businesses received non-conformances because management reviews did not address food safety culture performance and because internal auditing was not performed adequately.

How to avoid common non-conformances

Follow the tips below to avoid the non-conformances listed above.

Have a fresh set of eyes inspect your facility for hygiene issues related to the design, construction and maintenance of premises and equipment. This could be an expert from a sister site or an external consultant. The document Hygienic Design Principles, by EHEDG provides excellent (free) guidance.

Inspect all external doors from the inside. If you can see daylight around the edges, or if there is any gap wider than a pencil, then pest-proofing is needed. Ask your pest contractor to install it.

Keep doors closed during production to keep out pests, dust, birds and other sources of contamination.

Use a new/different internal auditor or external consultant to check your chemical control systems and traceability systems against the requirements of your food safety standard, to make sure each part of each clause is adequately addressed.

Keep storage areas well-organised, with clearly marked areas to segregate materials that pose a contamination risk, including allergens.

Close all containers, sacks and bags of raw materials when not in use.

Label all chemical containers and refresh faded or worn labels.

Check that pest contractors’ activities meet the requirements of your standard: are the monitoring and reporting documents adequate and available; are pesticides selected properly and their usage recorded; are any infestations dealt with quickly?

Add agenda items to management meeting agendas for food safety culture-related KPIs.

Ask an external expert to review your food safety plan to check that all hazards have been addressed, including microbiological, physical, chemical, fraud-related, intentional malicious contamination and allergens. Hazards in raw materials, hazards introduced during handling and hazards that survive processing steps all need to be identified.

Final thoughts

To pass a food safety audit you need to be compliant with the food safety standard you are being audited to… which means having few (or no) non-conformances. However, the main aim of avoiding non-conformances is to have a robust and well-implemented food safety program so that the food you make is safe for consumers.

Passing a food safety audit is not about obtaining a certificate or a gold star – it is about establishing a sound food safety program in your facility to protect your brand, your buyer, and your bottom line. [modified from] The Safe Food Quality Institute

Sources:

🍏SQFI (2023) Non-conformances in Edition 9

🍏Jensen Farms Outbreak CDC Report and FDA Report

🍏EHEDG Guidance Document: Principles of Hygienic Design

Food Fraud: Are Big or Small Businesses Riskier?

People are sometimes surprised when they hear me say that large food manufacturers and large retail chains have lower rates of food fraud than independent retailers and small food businesses. For people outside the food industry, I guess that’s a reflection of their mistrust of large corporations.

Industry insiders know that big businesses generally have more resources than small businesses when it comes to detecting and preventing food fraud in their supply chains. In addition, big businesses usually also have very valuable brands which could be severely damaged if they were to knowingly, or even accidentally, sell products affected by food fraud.

Most of the technical professionals I know in large retail chains are extremely diligent experts who are well aware of the risks posed by food fraud to their consumers and their brands. Better still, large retailers have the power to ‘force’ their suppliers - food manufacturers - to also be diligent about food fraud risks.

A recently published survey has data to support my theory. In the survey, large food business operators (retailers) performed significantly better than other operators when their foods were tested for authenticity, adulteration, labelling compliance and contamination.

Of 1010 food samples purchased in 2020 in England and Wales, the average non-compliance rate was 18% across all businesses, but only 7% for large businesses.

🍏 Source: Retail Surveillance Sampling Programme during Covid-19 pandemic 🍏

Chemical Hazards in Soy-based Foods and Supplements

Germany’s Bundesinstitut für Risikobewertung (BfR) has flagged possible health risks from consuming too much soy in products such as soy milk and soy-based meat alternatives.

The high concentration of isoflavones and other hormone-like chemical compounds which occur naturally in soy could pose a risk for people with estrogen-dependent diseases such as breast or uterine cancer. The risk could be especially high for people who choose predominantly plant-based diets, say the BfR.

There are also dietary supplements that purposefully contain high doses of isolated isoflavones from soy being marketed in Germany. However, the BfR notes that long-term studies on the safety of food preparations containing isoflavones are not yet available.

Our food safety news is expertly curated (by me!), so you get only the most interesting, focused information from around the globe. Click the link below to view.

Food Safety News and Resources

25 September | Food Safety News and Free Resources | Nine children dead from foodborne illness (Cote D’Ivoire) | Children poisoned by adulterated cookies (South Africa) | Multiple botulism cases and one death linked to sardines (France) | Packages of cut butternut squash recalled due to

What you missed in last week’s email

Greenhouse gas emissions from food - a contrarian perspective

The food safety aspects of washing rice

That’s interesting: red meat allergies are becoming more common

How the mafia profit from tinned tomatoes

Food fraud news and incidents

Below for paying subscribers: Food fraud news and incident reports (audio 🎧 is now at the top of the page)

📌 Food Fraud News 📌

In this week’s food fraud news:

Shocking results from meat species adulteration tests;

Surprisingly good fish mislabelling results in UK survey;

Basmati rice fraud;

Illicit watermelons;

Fake wine made with chemicals, dyes and grape flavour seized;

Russian organised crime boss accused of making millions from illegal seafood trading.

Shocking meat results

Twenty percent of minced meat and processed meat samples (n = 300), including burgers, mince, pies, ready meals, curries, kebabs and sausages, purchased from retail outlets in England and Wales contained meat species that the consumer would not expect to find. The worst-affected meat type was