172 | Emerging Food Safety Risks | Reduce Your Food Waste in 2025 |

Plus, steak tartare done well

Emerging Food Safety Risks (2025 update);

How to reduce your food waste;

Food Safety News and Resources;

Mr Bean at the restaurant (just for fun);

Food fraud news, emerging issues and recent incidents.

I’ve got a fabulous guest post from a food waste reduction expert in this week’s issue! Read on for that.

Hi, welcome to Issue 172 of The Rotten Apple, which features a breakdown of the European Food Safety Authority’s emerging risks report and an inspirational dive into practical methods for reducing food waste in food businesses.

There’s a very unusual warning for dog food in this week’s food safety news roundup (never thought I’d be using the phrase ‘werewolf syndrome’ in this newsletter!). And an update on the tuna adulteration scandal I reported on last month.

Thanks for being here,

Karen

P.S. This week we welcome new subscribers from an enzyme company in Germany, a food safety training company in the US, a fruit company in the UK and a donut maker. Welcome 👋 Vilma, Ylang, ‘Technical’, Michelle and Fiona 👋, thank you for supporting my work.

Emerging Food Safety Risks (2025 update)

The European Food Safety Agency has released a report on emerging food safety risks. Thirty-two potential risks were presented for consideration to an expert panel, with 5 deemed to be emerging risks, 7 deemed “not emerging” and 20 undetermined because more information is needed.

The 5 emerging risks are: Epizootic haemorrhagic disease; Pathogen spillover of Henipavirions driven by environmental changes; Alcohol replacement drinks; Rare earth elements; Z15 nanomaterial used in wastewater treatment plants in Ireland and the EU.

Are these new risks actually relevant to food safety practices in food businesses? (spoiler alert: many are not)

For food safety professionals needing to understand new hazards in supply chains, there are a few immediate takeaways to be gleaned. In addition, the report describes a number of risks that will likely become more impactful in the coming years.

Find out which risks you need to know about by reading this month’s supplement for paying subscribers where I break down the relevance and importance of the risks discussed by the expert network, in plain English without fluff and filler.

🍏 Get the whole story at this link (for paying subscribers) 🍏

Reduce Your Food Waste in 2025

By Leanne Singleton of FoodSure

What’s on the sustainability agenda for your food business in 2025? As environmental requirements continue to evolve, key goals include achieving zero waste to landfill, reducing greenhouse gas emissions, increasing energy efficiency, and using water responsibly.

Reducing food waste is an excellent starting point that positively impacts all these areas. Additionally, research has shown that for every dollar invested in reducing food waste, businesses can save $14 in operating costs.

Maximising impact

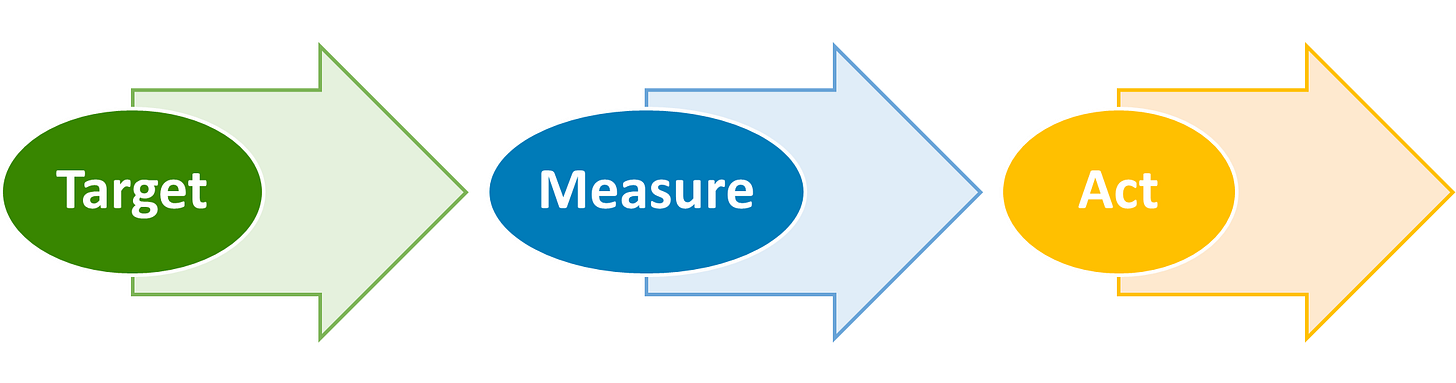

The Target – Measure – Act approach is a commonly used methodology for addressing food waste. It involves focusing on food waste, assessing the current status, and formulating the actions required to meet objectives and targets.

Target: Determine measurable food waste reduction objectives and targets within your business and across your supply chain.

Measure: Determine your food waste baseline as a whole and for individual functions/production processes to prioritise actions.

Act: Identify your food waste hotspots, determine causes of waste and potential solutions, and reduce, redirect or repurpose food waste within your business and across your supply chain.

Having a cross-functional team with diverse expertise and skills is essential to systematically reduce food waste. Think of it as the sustainability counterpart to a HACCP food safety team, where representation from various business functions provides valuable insights and engagement opportunities for reducing food waste.

Step 1: Target - Set objectives and targets to reduce, redirect or repurpose food waste

The overarching objective to meet the UN Sustainable Development Goals (SDGs) is to halve food waste by 2030. However, a food business will require multiple objectives to work towards this broad target.

The primary aim is to reduce food waste at the source whenever possible. Subsequently, the focus should be on redistributing safe, edible food to food rescue organisations or repurposing food waste into high-value uses such as pet food or animal feed. Examples of objectives to reduce food waste within a business may include:

· Establishing a baseline of food waste to identify which business functions and production processes generate the most food waste by volume and/or value, using existing data from procurement, production, packing, and waste management sources.

· Identifying data gaps in food waste reporting to improve the accuracy of food waste data for subsequent reporting.

· Assessing production and packing processes to pinpoint food waste hotspots, applying root cause analysis to determine causes, and implementing solutions to reduce food waste.

· Determining food waste metrics to be reported to provide real-time monitoring and performance of food waste reduction actions.

Objectives to reduce food waste across a supply chain may include:

· Engaging with upstream suppliers and downstream service providers and retailers to collaboratively identify supply chain hotspots and opportunities to reduce food waste through a series of in person and remote workshops.

· Revising procurement contracts to include clear expectations for suppliers to actively reduce food waste in their procurement and production processes.

Example: A vegetable processor targeted food waste reduction for their highest value and volume products to increase yields. A cross-functional team with Corporate and site representatives was formed. The initiative was so successful at the plant that it gained significant momentum across the corporate business leading to a strategic food waste action program being rolled out to 2 other sites.

Step 2: Measure your food waste baseline

Measuring food waste helps identify the processes and materials that generate the most waste, allowing businesses to prioritise actions to tackle the highest volume or highest value food waste. This doesn’t have to be an exact figure, an approximation is an acceptable starting point.

The World Resource Institute's, (WRI), Food Loss and Waste Accounting and Reporting Standard provides guidance on a range of measurements that can be used.

Many businesses we've worked with were unaware of the full extent of their food waste or the total volume of waste across their operations. Businesses often have food waste tracking systems in place upstream to packing, but not downstream to the retail sale of their products. This limits opportunities to identify hotspots in retailer and consumer practices.

A surprising find for our vegetable processor was the fate of waste products that were supposed to go to an organic composter. When they scrutinised waste disposal records they discovered inedible food waste and manufacturing by-products including dry ingredients intended for organic composting were often diverted to landfill by contractors seeking the cheapest option for disposal.

Step 3: Act – Develop a food waste action plan

Once you have established targets and measured your food waste, you can develop an action plan tailored to your specific products and processes.

Learnings from businesses

Many businesses have focused on reducing food waste at the end of their value-adding processes, only to realise that the real gains were made upstream.

Our vegetable processor found they could significantly increase their yield and reduce waste by optimising post-harvest transport, receival, and storage of a material they had previously disregarded as a low-cost commodity.

Most food processing systems are built for flexibility, however this comes with inherent complexities as the process lines are not designed for specific products. An example is conveyors that can cause damage to fragile products due to design and speed issues.

Equipment functionality, design and reliability are key drivers of food waste in automated processes. Examples include false rejects due to condensate on optical sorter cameras.

Another food manufacturer had up to a 10% failure rate on automated packing equipment for a high-value dairy product with a labour-intensive process to repack.

Other challenges we’ve found when working with food manufacturers is the capability of material accounting systems to incorporate part-used and returned ingredients in subsequent batches.

The use of liquid ingredients presents a different set of issues with around 15% of product wasted due to multiple transfer steps and retention in pipework and tanks. Similarly, some packaging formats retain highly viscous products that can’t be fully extracted.

Lastly, there are many instances where food waste could be reduced if the business had the equipment to capture rejected product for rework, with the added benefit of maximising yield and avoiding disposal fees.

In summary

There are numerous opportunities to reduce food waste across all businesses, with the most significant impact coming from small, incremental changes across functions and processes.

Begin by cultivating a mindset and culture that deems food waste unacceptable. Then, prioritise product and process improvements, along with innovations using technology and equipment, to save money, increase profits, and reduce environmental impact.

Make 2025 a year of impact on food waste.

Get in touch with Leanne on LinkedIn (Leanne Singleton | LinkedIn) - she’d love to help your business reduce its food waste - and follow her for regular tips on how to reduce food waste in any business. Aussies: follow Leanne for news of an interim Australian Standard on Food Loss and Waste Management Systems which is due to be published in March.

Food Safety News and Resources

Our news and resources section has not-boring food safety news plus links to free webinars and guidance documents. This week: an extremely strange warning about dog food (never thought I’d be writing the words ‘werewolf syndrome’ in this newsletter!) plus good results for phthalates in foods in Canada.

Click the preview below to access it.

Mr Bean at the restaurant (Just for Fun)

We all need to treat ourselves at times. In this 9 minute video, Mr Bean enjoys a birthday dinner with himself and accidentally orders steak tartare.

NEXT WEEK: Join me for a deep dive into the spate of poisonings and deaths linked to convenience store foods in South Africa.

Below for paying subscribers: Food fraud news, horizon scanning and incident reports

📌 Food Fraud News 📌

In this week’s food fraud news:

📌 Vitamin tuna strikes again;

📌 Test methods for hazelnuts, milk and juice;

📌 Warnings for blueberries and palm oil;

📌 Incidents affecting icecream and tea.

Vitamin tuna strikes again!

Last month I published a warning about a food fraud that has been dubbed ‘vitamin tuna’, based on information coming out of Vietnam, a major global exporter of seafood.

Now, incidences of