Issue #92 | Mystery Toxin Solved? | Food Scientists are 'Baddies'? | Sanitising Harvest Equipment |

2023-12-06

Welcome to The Rotten Apple, an inside view of food integrity for professionals, policy-makers and purveyors. Subscribe for weekly insights, latest news and emerging trends in food safety, food authenticity and sustainable supply chains.

Training Reminder (HACCP and Food Safety Systems for Complete Newbies is this Thursday)

Mystery toxin in tara flour identified (perhaps) by toxicologists

Are food scientists the ‘baddies’ for making highly processed foods dangerously addictive?

News and Resources Roundup

How to sanitise harvest equipment to protect consumers from food poisoning

Food fraud incidents, updates and emerging issues

Hello lovely readers!

Welcome to Issue 92 of The Rotten Apple, where I ask tricky questions 🤔 about the ethics of food science.

This week’s big question is about the role of food scientists in food-related health problems like obesity. Are food scientists the “baddies”? It’s a tricky question and I would love to know what you think about it (join the conversation here).

I love (loooove) it when scientists answer pressing problems. Last week, researchers from the University of Mississippi published the results of their investigation into a mysterious ingredient that seemed to cause hundreds of (unsolved) food borne illnesses last year. They did the research in record time while the food company, its suppliers and the regulators all appeared to sit on their hands. Yay.

Our food safety news this week has a couple of good free webinars for your edification plus updates on British eggs, botulism in Vietnam and arsenic in juice. Food fraud news this week includes news of a very impressive new authentication method that can tell the difference between salmon that is wild-caught and farmed (next level!).

If you like this newsletter, be sure to share it with your networks, and enjoy this week’s issue.

Karen

P.S. Reminder: our second live training event is on this week. It’s for people who are new to food safety concepts like HACCP and food safety management systems - I’ll explain it all in plain English and answer your questions in real-time. Everyone is welcome. Click the button to learn more.

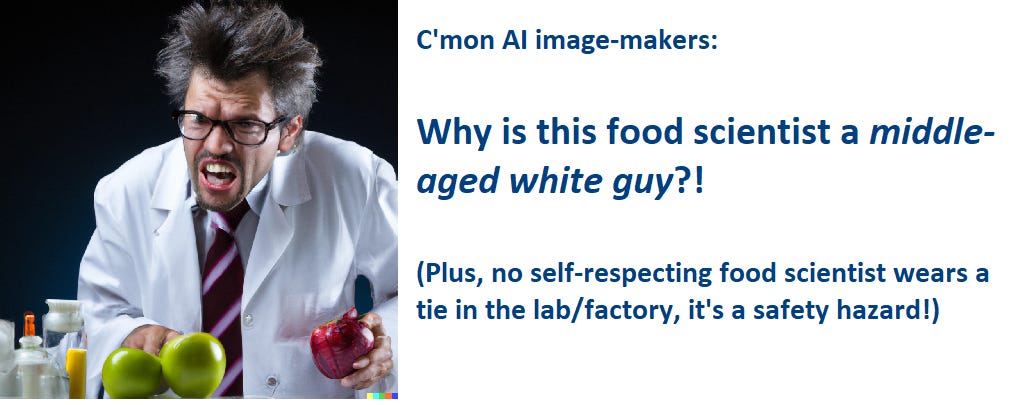

Cover image: What you get if you ask an AI image generator for “an evil food scientist” 😂

HACCP and Food Safety Systems for Complete Beginners

This training is for you if you are

completely new to HACCP and want to know how it works in food manufacturing, or;

you are a supplier to the food industry and want to know where you fit with food safety, or;

you are wondering if a career in food safety is right for you, or;

you just need a plain English explanation of all the acronymns!…

Then this training is for you.

Everyone is welcome, so spread the word.

Mystery Toxin Update

In 2022, a bunch of people became seriously ill with liver functioning issues that required hospitalisations and surgery, after eating meal-topper ‘crumbles’ marketed by a company called Daily Harvest. At least 390 people were affected and 133 people were hospitalised.

No one knew why the food was making people so sick.

The brand owner was accused of responding too slowly. They initially blamed consumers for not following on-pack cooking directions. Testing revealed nothing: no food pathogens, no pesticide residues, no mycotoxins.

Months after the first illnesses were reported, Daily Harvest released a statement saying they think the illnesses were caused by a toxin in an ingredient called tara (protein) flour. But they couldn’t say exactly what component of the tara flour was toxic.

This was bad. As a food safety specialist, it’s hard to do your job of protecting consumers from hazards if you don’t know what those hazards are.

At the same time, the FDA said they had handed the case from their outbreak team to a different, unspecified group. They refused to say for sure what caused consumers to become so seriously ill. They said they would continue to “evaluate which components of this product may have caused these illnesses” and that their investigation is “ongoing”. Since then: nothing.

New Information

Now, researchers from the National Center for Natural Products Research, School of Pharmacy, University of Mississippi, have published a paper which describes their investigation into the components of tara flour. They were looking for the compound that made people sick.

It looks like they have found the smoking gun. (Okay pedants, they call it a “working hypothesis”).

Their investigations first ruled out known chemical toxicants like aflatoxins and heavy metals in the tara flour. They also checked DNA from the tara protein flour to make sure it was genuinely derived from the Tara spinosa plant, as its supplier claimed. It was.

Next they looked at amino acids in the flour and found a few that were suspect. One in particular, called baikiain, seemed like it could be the toxic agent in the flour, because it is present in large amounts, has been found in toxic mushrooms and closely resembles chemicals that can catastrophically disrupt enzymes in humans.

After doing in-vitro tests (= in-glass, in test tubes), they performed in-vivo (‘in life’) tests on mice to see if the compound was toxic. The results led them to assert that chemicals produced in the body when baikiain is metabolised can cause adverse events when tara protein flour is eaten.

What can we learn from this?

There is less oversight of new ‘natural’ food ingredients than many consumers might imagine.

Just because a food or ingredient is ‘natural’, it is not necessarily safe.

It is hard to know what might cause food safety problems when dealing with new ingredients which have not been extensively studied.

🍏 For more on this story see Issue #44, Issue #46, and Issue #64 🍏

🍏 Main source: Chittiboyina, A.G., et. al. (2023). Is Baikiain in Tara Flour a Causative Agent for the Adverse Events Associated with the Recalled Frozen French Lentil & Leek Crumbles Food Product? - A Working Hypothesis. doi: https://doi.org/10.1021/acs.chemrestox.3c00100. 🍏

Dangerous Ultra-Processed Foods - Are We the Bad Guys?!

One of the jobs my team was given, when I was a food product development nerd in the 1990s was doubling pack sizes for the high-fat, high-salt snacks our company made.

Why bigger pack sizes? Because packaging material is expensive and chips are cheap. Put more in a bag and your profit margins go up.

At the time a ‘normal’ Australian single-serve package of potato chips (‘crisps’) was about the size of an adult hand. Australian per-capita consumption of savoury snacks was low, at 2.5 kg per year, compared to the US, where annual per capita consumption was 7.0 kg, and Britain, with 4.5 kg.

We doubled the pack sizes over the next five to ten years. The company I worked for got Australians to eat more snacks, and I was part of that. Am I a baddy?

Shockingly, we had already reintroduced MSG flavour enhancer to certain snack lines after seeing a drop in sales after removing it, even though consumers couldn’t tell the difference in blind tastings.

Consumers said they didn’t want MSG in their snacks. They said the MSG-free snacks tasted just as good. Problem was, they just didn’t eat as much of the MSG-free product, not even in free pre-launch tastings. MSG made people eat more snacks. And more snacks equals more profit. We put the MSG back.

What’s wrong with ultra-processed foods anyway?

Ultra-processed foods are consistently being blamed for a range of major health problems in wealthy nations.

Every day, it seems, my online world is bombarded with nutrition research and commentary about how ultra-processed foods can lead to problems with gut microbiomes, weight gain, mood disorders, diabetes, and more. The latest news to light up the airwaves is about how a certain artificial sweetener causes cancer.

I don’t talk about nutrition in this newsletter. But if you are interested in this subject, the book Ultra-Processed People, The Science Behind the Food That Isn't Food By: Chris van Tulleken, is highly recommended, and said to be entertaining and compelling, as well as informative.

The book discusses how modern manufactured foods are designed to make us eat more than we need; and more of the foods that are not healthful. I think most of us would agree. But it’s uncomfortable knowing that we have a role in this ‘modern-day epidemic’.

How do food scientists contribute?

Food scientists - specifically product development technologists - are the people who go to work each day to make foods better. Not better for consumers: better for the companies who employ us. We are employed because we have a talent for finding ways to make foods cheaper, more attractive and more addictive. In the process, the foods we work on often become less healthful.

So does that make us ‘bad’? Are food scientists causing major health problems with our talent for creating foods that are cheap, attractive and addictive?

There’s no question in my mind that food companies behave ‘badly’ from a nutrition-public health perspective. But food companies do not exist to be ‘good’. They exist to make money for their shareholders.

Food companies make profits and grow by selling more food, more cheaply, to more people. Even the most ethical, natural, healthful, sustainable food companies want to sell more food more cheaply because that is a requirement for profits and growth; it’s built in to our global commercial environment.

The people who make big strategic decisions at food companies answer to the companies’ owners and shareholders. Their job is profits. They tell their underlings to make food faster, more cheaply and to sell more of it. Their teams deliver, because that is their job.

In my snackfood days, our product development department reported to the marketing director. Yes, we were technical people, but marketing was our reason for being. Our team existed to design better, cheaper products for the marketing team to sell. It was the marketing director who decided we needed bigger packs and MSG. She reported to the shareholders, and they wanted more profits.

I don’t think food scientists are the ‘baddies’ for delivering the outcomes our employers asked of us. We are doing our jobs. The ‘blame’ lies with the system which allows and encourages food companies to do ‘bad’ things to human health for profits.

Can we fix this?

Food-nerd conversations around this topic (see this forum thread in the International Food Safety and Quality Network) typically focus on three approaches to solving the ultra-processed unhealthy food problem:

educate consumers better so they don’t eat as much ultra-processed food;

regulate food products and advertising directly so consumers can’t buy as much ultra-processed food;

regulate and/or supervise food supply chains so less-processed food is cheaper and more readily available to all consumers.

I think we should also be encouraging investors and company owners to take a long hard look in the mirror and ask themselves which types of companies they would like to earn dividends from.

There are no easy fixes, but a multi-pronged approach that incorporates these four ideas is our only hope.

What do you think?

This post was inspired by IFSQN Forum Fellow GMO who started a thread on this topic (and suggested we check out this comedy sketch on YouTube that asks “Are we the baddies?”- very British, very funny).

You can check out the IFSQN conversation and join it here: https://www.ifsqn.com/forum/index.php/topic/45882-are-we-the-baddies/

Food Safety News and Resources

No ads, no sponsored content: our weekly roundup of global food safety news is carefully curated and only top-quality information makes the cut.

This week’s news includes: a free webinar about cybersecurity, PFAS in fish, arsenic in fruit juice and more.

Click below to access it.

News and Resources Roundup

12 June | Food Safety News and Free Resources | 💀 Multiple cases of botulism in Vietnam – different sources 💀 There were so many cases of botulism in Vietnam in May that a major hospital ran out of antitoxin. Four people who ate pork sausages in Ho Chi Minh City, and three people in another city who ate street food became ill and needed antitoxin. One person who got botulism from fish sauce died.

Sanitising Harvest Equipment: Why? How?

In last week’s issue, we explored fascinating insights from a lettuce Listeria outbreak. One of the things the lettuce company learned from the outbreak was that harvest equipment for leafy greens needs to be cleaned much more thoroughly than most of us might assume.

(Reminder: lettuce which was used in salads got contaminated with pathogenic bacteria when it came into contact with hard-to-clean parts of a harvesting machine. Lots of people got sick. Leafy greens are almost impossible to completely decontaminate by washing).

In short: harvest equipment for eaten-raw veg can cause outbreaks if it is not cleaned properly.

The problem: if you want to clean a harvester you usually have to do it at night, in a muddy (or dusty) field.

Key challenges are access to sufficient lighting and access to enough clean water.

Another major challenge, that we touched on last week, is in the design of harvesters – they usually are not designed for easy cleaning, and this is exacerbated when harvesters are switched from being used for veg that will be cooked prior to eating and crops like lettuce which are eaten raw.

I gained valuable insights into the challenges and solutions for harvester sanitation from Justin Kerr, Founder and CEO of Factor IV Solutions in a presentation he did for Virginia Tech in April.

In his presentation, Justin explains details of harvester sanitation processes. For example (who knew?!) he says that choosing the right pressure-washer tip on a hose is really important because you don’t want to use too much water when you are cleaning a harvester. Cleaning crews, he says, sometimes have to drive 26 miles to fill their water tanks from an approved water source. So they don’t want to run out of water before the job is done.

There are various types of detergents and sanitisers used for harvester sanitation, including chlorinated alkaline detergents, hydrogen peroxide peracetic acid, other acid detergents, alkaline degreasers, chlorine dioxide in both aqueous and gaseous formats, and even dry ice treatments for deep cleans. These are applied using a variety of foamers and hoses and even the “Good ol’ bucket and brush” method.

Achieving a verifiable result with a repeatable process is what a good harvester sanitation process is all about. Checking the concentration of the sanitiser (‘titrating’) and implementing verification methods that work in real-time can help achieve a reproducible result with different crews on different equipment.

Verification methods include: visual inspections; ATP swabbing with immediate feedback for the cleaning crew (this is great for training), other microbial swabs to build up a picture over time, and third-party inspections to hold cleaning contractors accountable.

If you are interested in the cleaning and sanitising of difficult-to-clean equipment, Justin’s talk is highly recommended. It starts at 22:37 of this YouTube replay:

What you missed in last week’s email

· Valuable Lessons from a Dole Lettuce Outbreak

· Are Quat Sanitisers as Safe as Everyone Thinks?

· How Does Salmonella Get Into Seafood?

· The History of Sushi (funny, good)

Below for paying subscribers: Food fraud news, incident reports, and emerging issues, plus an audio version that sounds super-husky as I recover from laryngitis…

📌 Food Fraud News 📌

Farmed and wild salmon can be differentiated and their geographical provenance checked with a new test method.

More than 500 samples of farmed and wild-caught salmon from Alaska, Norway, Iceland and Scotland were tested for authenticity using a new method which combined data from lipid profiles and elemental profiles obtained from two different mass spectrometry methods. The test was able to