163 | How to Ace a Food Safety Audit | Making Melons Safe Again |

Also, look out for a free subscription this month

This is The Rotten Apple, an inside view on food fraud and food safety for professionals, policy-makers and purveyors. Subscribe for insights, latest news and emerging trends straight to your inbox each Monday.

How to ace your next food safety audit;

Food safety champion makes melons great again;

Food Safety News and Resources;

Insight: Loud and jumbled food innovations;

Food fraud news, emerging issues and recent incidents.

Hello, food safety champion!

We have some fabulous, talented, smart people working in our industry, and today I want to mention two of them: 💖Elise from the US 💖and 🏆SP Singh 🏆 from Australia.

Elise is a long-time supporter of The Rotten Apple, and her special top-tier ‘Good Apple’ subscription helps me support students like Niek from The Netherlands, who requested my help for his thesis on food fraud in edible oils last month. Niek now has complimentary access to all the food fraud resources on this website, thanks to Elise’s generous support.

SP is the other person I want to mention. I doubt he’s even heard of this newsletter, but I’ve seen him present his work at various conferences and I’m always impressed by his willingness to find answers to tough questions, and share them in plain language. He works for the Australian NSW Department of Primary Industries – it’s a bit like a mini USDA – and was the brains (and brawn) behind a project that set out to make melons safe again. He succeeded. More on that shortly.

Also this week, a guide to help you sail through your next audit and insights from a food innovations conference.

Enjoy,

Karen

P.S. If you know a food safety champion for me to celebrate, please let me know.

Cover image: Freepik

Quick announcement: Substack gifts

Substack is the software I use to publish this newsletter. Today Substack’s team told me they will be contacting some of you to offer a free one-month subscription to this newsletter. This is a legitimate offer, so please consider accepting it.

If you’re chosen, and accept the gift from Substack…

You’ll get access to our complete set of resources for paying subscribers for $0 and

I’ll get the subscription fee, paid by Substack (win-win!)

How to Ace Your Next Food Safety Audit: A Step-by-Step Guide

Audits, argh. They are a pain in the neck for many food safety professionals, taking our time and attention away from proactive work and getting in the way of important projects. It often feels like we’ve barely finished one audit before the next one starts. Add in the time it takes to stay on top of all the different audit requirements and it’s no wonder food safety professionals find audits a disagreeable part of their jobs.

However, with the right preparation and mindset, you can turn your next audit into an opportunity for improvement rather than a source of stress. This short guide describes actionable steps to ace your next food safety audit and reduce the scramble. Let’s dive in!

1. Understand the requirements

It’s almost too obvious to include in this guide, but understanding the audit’s requirements is an absolute must-have for success audit. That means having a thorough understanding of the standard or regulation your company is being audited against.

External audits can come in the form of regulatory checks (often called ‘inspections’ rather than audits), second-party audits, which are audits by customers, and third-party audits, which are audits by certification bodies.

The requirements for each of these types of audits, and their durations are quite variable. A customer audit, for example, can take the form of a short visit to check your facility and systems or an in-depth and time-consuming process based on a long checklist or complicated standard.

For this step, you’ll need a copy of the audit standard or checklist and familiarity with its contents. To stay on top of changes to standards, keep a lookout for free webinars from the standard owner or certification body.

If you’re new to food safety systems, consider formal training in the relevant standard(s). Also, keep an eye out for guidance documents published by standards owners on specific topics such as food fraud or food safety culture which are usually very helpful for audit preparation.

2. Conduct a self-assessment

Most standards require food businesses to conduct internal audits which check that systems are working as they should throughout the year. However, internal auditors can easily overlook key areas of non-compliance, especially if they are very familiar with the system.

A self-assessment means checking that your systems meet the requirements of the standard. It allows you to identify gaps and correct areas of potential non-conformity before the audit. A self-assessment includes activities such as checking that documents are up to date; records are available; procedures reflect what is actually being done and the physical environment is clean and organised.

Top tip: If you don’t have time to do a complete self-assessment, check industry news for articles that list common non-conformances and focus your efforts on those areas. See past posts Top 5 Audit Non-conformances: BRCGS spills the beans on a year of audits and Top Food Safety Non-Conformances and How to Avoid Them for inspiration.

3. Get your docs ready

Auditors love an organised set of documents! It saves them from having to waste their time searching through mounds of paper or digital files looking for answers and allows them to focus on important food safety issues rather than navigating paperwork tangles.

If your system is organised so that auditors can easily find their way around, they’ll be more relaxed and you won’t need to sit and hold their hand throughout the audit, freeing you up to get on with other tasks.

Whether your food safety program is published with sophisticated software or filed in simple paper folders, it should have a contents page (or electronic file) that names all the elements of the program and includes links or guidance to where each section is located.

If some of your records are supplied electronically by contractors, such as cleaning contractors or pest management professionals, be sure to include instructions or links for access to their records.

It goes without saying that you should make sure that all documents referenced in your program are available and accessible at the time of your audit. For example, make sure all paper folders are where they should be, check that you can log in to your contractors’ portals and ensure that electronic folders can be accessed from the right devices.

4. Borrow a colleague for a walk-through

If it has been a while since your last audit, it might be worth borrowing a fresh set of eyes to take on a walk-through of your facility. It’s easy to miss areas of non-compliance if you see them every day.

Tell your colleague – ideally someone who doesn’t go into food handling areas often - to help you look for problems such as inaccessible hand wash sinks, open ingredient containers, doors propped open, improper wearing of PPE, unlabelled WIP (work in progress), temporary maintenance solutions like cardboard or sticky tape, peeling paint, condensation drips, non-functioning lights, uncovered waste containers, empty hand soap dispensers and the like.

If you find something, fix it before the audit.

5. Reframe the audit for yourself and your team

If you’re anxious about an upcoming audit, or treat it as nothing more than an unwanted intrusion, your attitude is likely to rub off on your team. Auditors have a sixth sense for bad attitudes, and will not only pick up on it, but may also unwittingly reflect it back to you in their approach.

An auditor who feels unwelcome and unappreciated might even imagine that your company’s food safety culture is not up to scratch.

A good auditor will raise issues in a way that promotes a positive, rather than a defensive response from the auditee. But not all auditors are good. The trick to dealing with a difficult auditor is to imagine that the auditor has highlighted an issue with the aim of helping your business do better, not so they can give you a fail.

Most auditors are in the job because they want to use their expertise to help food businesses do better, and most genuinely want their work to result in better food safety outcomes for consumers. They are auditing to help your business make food safer every day - they certainly aren’t in it for the money.

Tips for reframing: Remind yourself that the auditor’s primary role is to help your business do better. Also remind yourself that auditors are subject to an unconscious bias that means they can feel like they haven’t done their job properly if they haven’t raised at least a few non-conformities.

6. Prepare your colleagues

This step is about making sure everyone knows what to expect on the audit day(s). Assign roles and responsibilities for various topic areas so everyone knows who is responsible for answering questions about each aspect of the food safety program.

Warn senior managers they may be asked questions about food safety culture, such as how they prioritise resources or handle staff turnover.

Top tip: Don’t forget that auditors are people too. Offer them a drink, make sure they have a space to work that is not too hot or cold, arrange a comfortable chair, check that they have brought something to eat, and arrange something for them if they haven’t.

7. Aim for transparency

The surest way to make an auditor suspicious is to try to hide problems or deny evidence. Be open and honest and make sure your colleagues know that this is the approach you want to take with auditors. When issues are pointed out, avoid acting defensively, but stay calm.

8. Correct problems on the spot if you can

Most auditors are fine with instant corrections to minor problems, so don’t hesitate to fix problems while you are with the auditor if you can. For example, if you are authorised to update a document where the auditor has found a minor error, you could make the correction during the audit.

Instant corrections save the auditor from having to write up a non-conformance and they save you from having to document a corrective action process after the audit.

9. Get clarification and push back if needed

Auditors make mistakes, and different auditors have different ideas about how things should be done. If you don’t agree with something an auditor says, make sure to discuss it with them as soon as they say it. This can help prevent small misunderstandings from becoming big ones.

For example, if an auditor says they have found a problem with something that previous auditors did not highlight, it’s fine to question their opinion. They could be working with an incorrect assumption or may have misjudged the evidence.

When you seek clarification you are giving the auditor a chance for them to provide you with current best practices and help your business improve. On the other hand, if they realise they have misunderstood a situation, your input might save them from an embarrassing mistake. Either way, you are doing them a favour.

If you are not one hundred percent clear on any findings the auditor describes at their closing meeting, ask them to clarify before they leave. If you still aren’t satisfied, request more details in writing too, and check that the auditor has evidence to back up their findings.

Truly problematic audit results and auditor behaviour can be discussed with your certification body if you are not able to resolve issues with the auditor.

Final thoughts

Food safety audits are not just about compliance, they are an opportunity to get feedback on your systems and stay up to date with best practices in food safety. By following the steps outlined in this guide, you can transform potential stress into a structured process that fosters confidence and promotes teamwork.

Embrace the feedback from audits as a pathway to continuous improvement, remembering that the ultimate goal is to improve food safety outcomes and protect consumers. And remember, if you aren’t convinced about the auditor’s findings, be sure to seek clarification.

Making Melons Great Again

How a food safety initiative for melons eliminated recalls and (almost certainly) saved lives

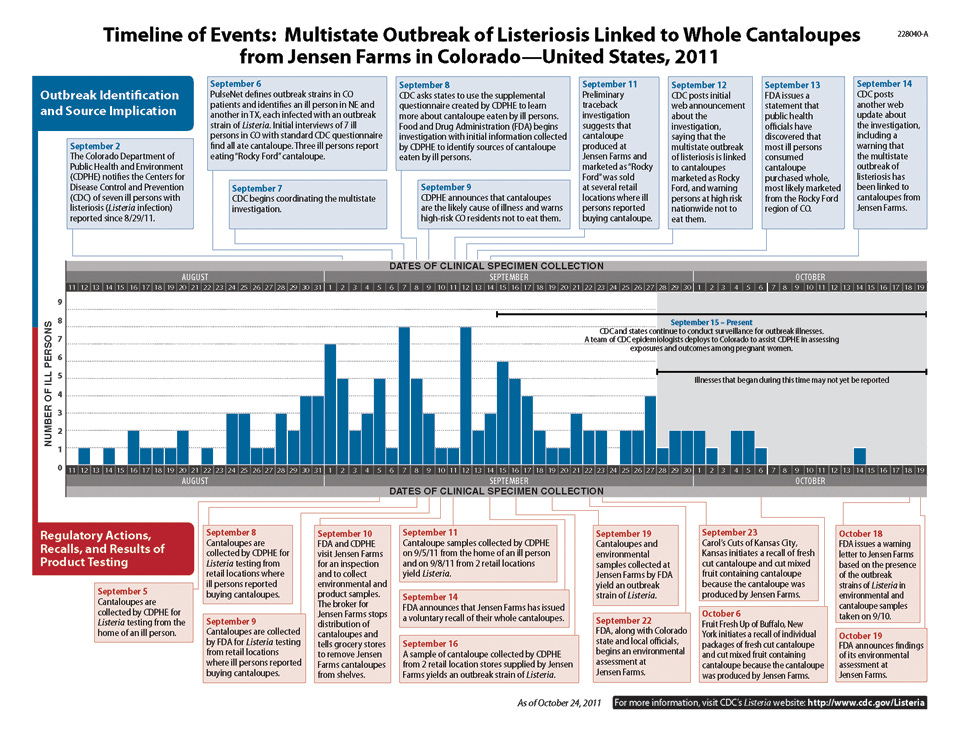

Who remembers the cantaloupe Listeria outbreak of 2011? It was the deadliest foodborne illness outbreak in the USA since outbreak records began in the 1970s, sickening at least 147 people and killing 33. It was followed by another deadly US cantaloupe outbreak, which killed 3 people, this time from Salmonella, the following year.

In the decade since there have been multiple outbreaks linked to melons, including two major outbreaks in Australia in 2016 and 2018 caused by Salmonella and Listeria respectively.

The Australian melon industry was badly affected by the 2018 outbreak, and growers left the industry as consumer confidence plummeted and sales decreased. Something had to be done so the industry partnered with government agencies to create an initiative to safeguard melon consumers from food safety risk, called – appropriately – Safe Melons.

The initiative was led by Dr Sukhvinder Pal (SP) Singh, a food safety champion in the Australian produce industry, and one smart cookie.

It proved to be a resounding success, reaching an astonishing 99 percent of the country's commercial melon growers and resulting in a reduction in food safety incidents for melons in Australia to zero for the last six years. Meanwhile, incidents have continued in other countries, such as the 2023 Salmonella outbreak from cantaloupes in the USA which resulted in 407 cases, 158 hospitalisations and 6 deaths, or the 2021 Salmonella outbreak linked to Galia melons in the United Kingdom.

Here’s how it worked.

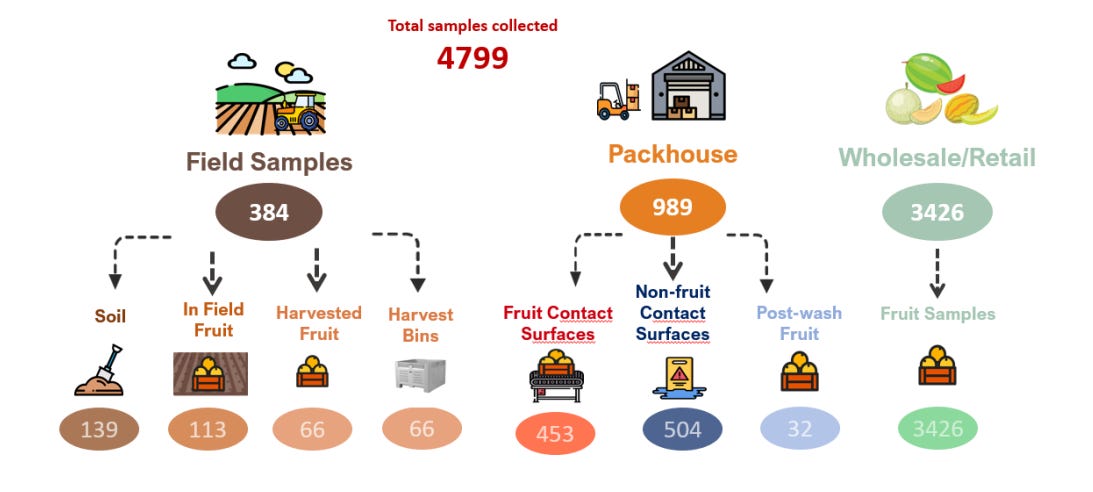

The initiative used a two-pronged approach: monitoring and support. The monitoring component was a confidential microbial food safety surveillance program designed to function as an early warning system to predict food safety failures and prevent them from becoming a crisis.

The monitoring aimed to detect Listeria monocytogenes, Salmonella species and Shiga-toxin E. coli (O157:H7) in samples collected from various stages of the growing, harvesting and post-harvest handling stages of the supply chain.

The sampling plan was scientifically designed to be inclusive of all melon types and all melon-growing regions in Australia. Samples were collected from melon production fields (soil, fruit, and harvesting equipment), processing facilities (contact and non-contact surfaces and fruit) and markets (wholesale and retail) with a target of 1,300 samples per year for three years.

Any problematic results – for example, when Salmonella was detected multiple times in a processing environment after an extreme weather event in 2022, or when Listeria monocytogenes was detected in samples taken because of a flood in 2023 – the results were reported back to the affected growers and processors immediately, along with technical recommendations to mitigate risks and promote continual improvements.

During and after the project, the microbial data was also anonymised and aggregated so results at regional, state and national levels could be shared with various audiences. Case studies on growers and packers who achieved good food safety outcomes were also shared to champion food safety leaders in the industry.

The second component of the project, support, aimed to increase the food safety knowledge of growers and convert knowledge into practice and behavioural change. It included site visits and one-on-one consultations with major growers, regional workshops and ‘roadshows’, education for regulatory personnel and policy-makers, and even a food safety helpdesk service to address melon-related food safety enquiries.

Growers and packing shed staff were coached in the adoption of a food safety toolbox and best practice guides were shared. Food safety experts walked through production fields and processing facilities with growers, helping with microbial hazard assessments and providing risk mitigation advice.

The helpdesk allowed growers and regulatory officials to benefit from unbiased technical advice when they needed to make decisions about food safety practices.

Questions posed to the helpdesk included requests for help with environmental monitoring programs, postharvest packaging and decay, responses to extreme weather events, postharvest wash water quality, sanitisers and fungicides, fertiliser selection, and wildlife incursion management.

Says SP of the project “The success of this project was dependent on the grower/packer’s engagement on highly sensitive topic of microbial food safety. The level of engagement clearly indicates that stakeholders trust the monitoring and support services provided by an independent team of experts and were interested in risk mitigation.” Singh (2024)

The project concluded with an evaluation of its outcomes compared to the key performance indicators (KPIs) set at the outset, a concise list of recommendations for continued melon safety, and recommendations for future research and development projects.

The outcome was a success, reducing the number of melon-related food safety incidents to zero, contributing to increased consumer confidence in Australian melons and almost certainly saving lives that would have been lost if there had been another serious Listeria or Salmonella outbreak. Well done.

“Zero product recalls and food safety incidents are perceived as an ambitious and unrealistic goal”, says SP in the project report, “but it is the minimum goal that all industries should be aiming for.” Agreed!

In short: An industry, in partnership with government organisations and private sector investment, created a project to reduce foodborne illness outbreaks from its products 🍏 The project was carefully designed with specific, measurable outcomes and key performance indicators (KPIs) 🍏 The project included confidential microbiological surveillance with problematic results reported immediately to growers and processors so risks could be mitigated promptly 🍏 It also included support for growers and processors to increase food safety knowledge and affect behaviour change 🍏 The project succeeded in engaging with more than 99% of relevant growers 🍏 It reduced the number of food safety incidents in the industry to zero and the number has remained at zero for six years 🍏 A job well done 🍏

Main source:

Singh, S.P. (2024). Melon food safety -monitoring and support. [online] Available at: https://www.horticulture.com.au/globalassets/laserfiche/assets/project-reports/vm20005/vm20005-final-report.pdf

Food Safety News and Resources

Our news and resources section has not-boring food safety news plus links to free webinars and guidance documents: no ads, no sponsored content, only resources that I believe will be genuinely helpful for you.

Click the preview below to access it.

Insight: Professor Chris Elliott on food innovation

Last week Professor Chris Elliott wrote about his experience at the inaugural Food Revolution conference in Italy. He mentioned that he had learned about the tough regulatory processes for novel foods in Europe, saying they are reassuring for food safety practitioners but frustrating for entrepreneurs, and spoke about the state of food research funding.

Among his insights, there was one that stood out for me:

“There are many voices all making noises about the problems and best solutions [in food systems]. I think this can be best described as a cacophony, i.e. a sense of loud, jumbled, and often unpleasant sounds all happening at once.” Prof. Chris Elliott

Professor Elliott calls for the cacophony of competing voices to be replaced by a series of well-thought-through changes, what he calls a transitional roadmap rather than a food revolution. I couldn’t agree more.

My mission is to protect you from the “loud and jumbled sounds” of food system commentary, by sharing only information that will move the dial for you, your teams and the people who eat your food. If you ever feel I’m straying from that path, please let me know.

Below for paying subscribers: Food fraud news, horizon scanning and incident reports

📌 Food Fraud News 📌

In this week’s food fraud news:

📌 Stolen cheese;

📌 Fraud in plant-based food names;

📌 Incidents with sugar, sauces, Italian dairy foods and more;

📌 Warning for meat.