223 | What 795 Food Fraud Cases Tell Us About Risk | Pesticide MRLs | Cereulide Root Cause

+ Insights from the brains trust

Save the date: food fraud webinar next week

Food fraud and food safety: latest research

Pesticide MRLs: the quiet illusion of food safety

Cereulide root cause - new insights

Tuna tossing

Food fraud news, emerging issues and recent incidents

Hi,

Welcome to Issue 223. Thank you for joining me. And a special huge thank you to 👏👏 Sonia, Walter, Becky, Technical and Nery 👏👏 for upgrading to paid subscriptions. Nery has been reading since 2022, proving it’s never too late to jump aboard and get access to our premium resources.

One of my favourite things about this newsletter is the huge global brains trust it’s become. You’re a fabulous bunch of people, so generous with your knowledge. This week’s issue features input from readers and colleagues in Germany, Italy, Greece and the United Kingdom!

You’ll learn about pesticides from Cesare, cereulide root causes from Athina, get a chance to hear about food fraud predictions from Asli in Germany and more.

Enjoy,

Karen

P.S. Happy Australia Day to all my wonderful Aussie readers (Oi, Oi, Oi!)

Save the date

Our next live event is on Tuesday next week (3rd Feb). Click the link below for all the details.

Erratum

BRCGS does not stand for British Retail Consortium… but for Brand Reputation through Compliance - Global Standards (what a mouthful!). Thank you to readers Ashley and Sonia from the UK for letting me know.

British Retail Consortium still exists, but I’m told it is no longer associated with the standards.

What 795 Food Fraud Cases Tell Us About Real Risk

We already know that when food is affected by food fraud, there are food safety risks.

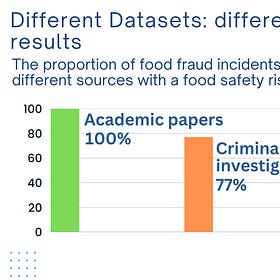

However, what hasn’t been quantified until recently is the proportion of food fraud incidents that are also potential food safety incidents. A group of researchers from Wageningen University (The Netherlands) is trying to change that.

In this month’s special supplement for paying subscribers, I extract the most pertinent insights from a paper published by them in the journal Foods last month, and discover what we can do differently in the food and related industries to reduce the food safety impacts of food fraud.

Click the preview box below to read.

The Food Safety Impact of Food Fraud: What 795 Food Fraud Cases Tell Us About Real Risk

This special supplement explores the food safety risks posed by food fraud, as revealed by new research from Europe.

Pesticide MRLs: The quiet illusion of safety

A guest post by Cesare Varallo

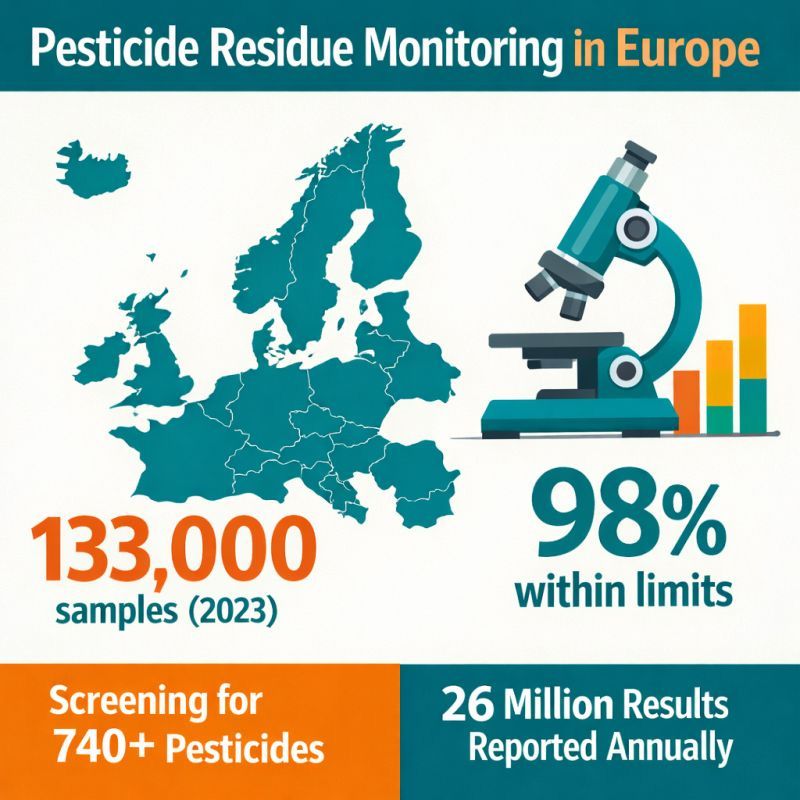

In 2023, inspection services across the European Union, plus Iceland and Norway, analysed around 133,000 food samples for pesticide residues. 𝟗𝟖% 𝐰𝐞𝐫𝐞 𝐜𝐨𝐦𝐩𝐥𝐢𝐚𝐧𝐭 according to the European Food Safety Authority (EFSA) report, meaning either residue-free or within the applicable Maximum Residue Levels (MRLs).

Of the residual 2%, truth be told, 1% is still borderline compliant, because taking into account measurement uncertainty, the residues found were acceptable according to the EU legislation.

Possibly the EFSA publicised a 2% non compliance rate to raise more awareness of the issue, but as a food safety leader, you would agree with me that hoping for the analytical uncertainty of the methods to get your consignments through border inspections is not a business strategy, it is Russian roulette.

At first glance, the overall data seems to confirm that the system works and the food is safe, at least for consumers.

And this is where the conversation usually stops: far too early if you are a food executive. Pesticide MRL violations are the most common notification in the European Union’s Rapid Alert System for Food and Feed (RASFF) system.

If 98% of samples are compliant, the 𝐫𝐞𝐦𝐚𝐢𝐧𝐢𝐧𝐠 𝟐% 𝐢𝐬 𝐰𝐡𝐞𝐫𝐞 𝐫𝐞𝐩𝐮𝐭𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐝𝐚𝐦𝐚𝐠𝐞, 𝐛𝐨𝐫𝐝𝐞𝐫 𝐫𝐞𝐣𝐞𝐜𝐭𝐢𝐨𝐧𝐬, 𝐚𝐧𝐝 𝐜𝐫𝐢𝐬𝐢𝐬 𝐦𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭 𝐭𝐞𝐧𝐝 𝐭𝐨 𝐜𝐨𝐧𝐜𝐞𝐧𝐭𝐫𝐚𝐭𝐞. Not because the system is failing, but because 𝐫𝐢𝐬𝐤 𝐢𝐬 𝐧𝐨𝐭 𝐞𝐯𝐞𝐧𝐥𝐲 𝐝𝐢𝐬𝐭𝐫𝐢𝐛𝐮𝐭𝐞𝐝. It clusters around specific commodities, countries of origin, production practices, and moments of regulatory transition. Analysing data, you can clearly see patterns, especially crossing commodities with countries of origin, and with specific active substances. Your risks are at those crossroads.

For food business leaders, the practical takeaway is not “we’re safe”. It is something more operational.

If you source globally, MRL compliance cannot sit at the end of the chain as a quality control checkbox and cannot be static. It has to sit as upstream as possible, as a procurement and supplier-management condition, and be verified downstream with targeted analysis based on your risk assessment.

That means asking 𝐪𝐮𝐞𝐬𝐭𝐢𝐨𝐧𝐬 𝐭𝐡𝐚𝐭 𝐚𝐫𝐞 𝐭𝐨𝐨 𝐨𝐟𝐭𝐞𝐧 𝐬𝐤𝐢𝐩𝐩𝐞𝐝:

Are suppliers working against current EU MRLs, or outdated internal specs/other countries’ limits?

Do residue monitoring plans reflect real analytical scopes, or marketing assurances?

Is there visibility on analytical methods, laboratory accreditation, and reliability of the systems, not just pass/fail results?

How are you monitoring changes in MRLs?

How fast can formulations or sourcing adapt when MRLs change - which they do, constantly?

In practice, many companies only discover how “alive” the MRL system is when a shipment is stopped at the border. By then, compliance is no longer a regulatory issue. It is a business problem and a cost mounting minute by minute.

To move upstream and limit the risk, you have several tools.

The first step is to source raw materials from reliable suppliers: known, audited on site, not selling at a price too cheap to be true, and with a mutual interest in long term cooperation.

The second is to bind such suppliers to certain guarantees, like providing, before shipment, an analytical report made by an EU-accredited lab. Do not accept shady certificates from unknown labs, and never 100% trust your suppliers. I never saw a non-compliant report in my life in such an instance. So keep samples of each consignment when you receive them, and test again to be sure everything is in order, at least unless the business relationship is mature.

Explore insurance possibilities and define clear contracts with your suppliers, defining beforehand who will be responsible for what. If the perishing of goods due to bad preservation can be the fault of many operators along the supply chain, the presence of pesticide residues often restricts the potential suspects to primary producers. Such operators and traders/exporters should be at least contractually bound to provide you with compliant goods for such parameters.

Try to avoid too many middlemen, brokers, and traders: keep as much control as possible on your supply chains.

Contracts, like insurance, do not solve compliance issues, but at least can mitigate potential damages in case of incidents.

The EFSA data doesn’t tell us that pesticide residues are out of control. Compliance is high, 𝐛𝐮𝐭 𝐲𝐨𝐮𝐫 𝐛𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐝𝐞𝐩𝐞𝐧𝐝𝐬 𝐨𝐧 𝐡𝐨𝐰 𝐬𝐞𝐫𝐢𝐨𝐮𝐬𝐥𝐲 𝐭𝐡𝐞 𝐥𝐚𝐬𝐭 𝟐% 𝐢𝐬 𝐦𝐚𝐧𝐚𝐠𝐞𝐝.

Compliance without a strategy becomes a cost.

Compliance with a strategy becomes an investment.

Sources:

EFSA infographic: https://lnkd.in/epiR-bKx

EFSA full report: European Union report on pesticide residues in food

About the author: Cesare Varallo is a food lawyer and regulatory strategist based in Italy, founder of Food Law Latest and Food Orbit, international speaker and guest lecturer at LUISS in Rome, and IFLR at Michigan State University. He works mostly around food law, food labelling, and food safety and authenticity issues, helping companies transform compliance into an investment and a competitive advantage.

Contact Cesare via LinkedIn or by writing to cesare.varallo@foodlawlatest.com

Cereulide root cause insights

Speculation continues, as the infant formula recall grows

The cereulide toxin in infant formula issue is now being acknowledged by other manufacturers, including Danone SA and Groupe Lactalis, which have initiated recalls in addition to Nestlé. And the ARA-enriched oil ingredient has been officially confirmed as the source (thank you to Mikko for letting me know where to find that notification!)

🍏 In case you missed it, we took a deep dive into cereulide and ARA-enriched oil production in Issue 222 🍏

A potential new root cause for the cereulide in infant formula problem has been proposed by reader Athina Chatzopoulou, BVM MSc PhD of ScieLab in Greece. She writes:

So many facts have not been disclosed! We still do not know what procedures were involved. We can’t even be certain of the methods used in detecting the toxin. So, here’s another scenario for these incidents.

CABIO Biotech (Wuhan) Co has been named as the supplier of Nestle’s toxin-containing ingredient, ARA-enriched oil.

ARA oil has traditionally been produced using the fungus Mortierella alpina. However, Nestlé’s supplier may have recently begun to use a different process.

In 2023, CABIO Biotech (Wuhan) was granted approval to use the microalgae Schizochytrium sp. to produce a Novel Food, an oil with DHA and ARA acids by the European Food Safety Authority (EFSA).

Since the initial approval, the production process has been amended, with an explanation added to the EFSA’s approval document. In fact, this happened in October 2025, only two months before Nestlé’s first announcement of its infant formula recall.

The revised production process involves the controlled growth of microalgae followed by extraction and refinement of the oil. An alkaline protease, derived from Bacillus licheniformis, is added to extract the crude oil from the biomass.

The alkaline protease, claimed to be of “food grade”, is not supposed to be active in the oil. Similarly, the extracted oil is claimed to be free of any viable cells. However, it is not known if the safety of the B. licheniformis and proteases used in the new ARA production process have been assessed.

Certain strains of B. licheniformis can produce a cereulide-like toxin and have been involved in food poisoning incidents.

Thank you, Athina, for your insights. A change in process, especially such a momentous change to fermentation processes, always carries risks of new and hard-to-predict hazards. Hopefully we’ll learn more in the coming weeks.

Tuna Tossing (Just for Fun)

In honour of Australia Day, I thought I’d share a local tradition from the town of Port Lincoln in South Australia.

Every January, the town hosts the Tuna Festival, Tunarama, to celebrate its history as the Southern Bluefin Tuna capital of the world. Southern Bluefin is said to be the best tuna, with a higher fat content, more buttery texture and deeper flavours than leaner tunas like yellowfin or albacore.

The Tuna Toss, a highlight of the festival, is a competition to see who can hurl a fish the farthest. Real tuna were initially used, but nowadays competitors throw a 10kg rubber replica fish with sometimes hilarious results.

Below for paying subscribers: Food fraud news, horizon scanning and incident reports

📌 Food Fraud News 📌

In this week’s food fraud news:

📌 Olive oil compliance discussed in new report

📌 Tax investigators examine suspected food fraudsters

📌 Warnings for cardamom, Atlantic salmon

📌 Faked speciality meats, ‘Scottish’ salmon fraud, and huge supplement sting

Did you know: Cardamom plants are extremely sensitive to pests and weather events, and harvesting is labour-intensive, contributing to cardamom’s status as one of the most expensive spices by weight, behind saffron and vanilla. (Source)