Issue #97 | Sustainable Labs | Biofilms Masterclass | Why Daily Harvest Used Toxic Ingredients | Hilarious Carbon Offsetting Explainer Video (Not Safe for Work)|

2023-07-17

Welcome to The Rotten Apple, an inside view of food integrity for professionals, policy-makers and purveyors. Subscribe for weekly insights, latest news and emerging trends in food safety, food authenticity and sustainable supply chains.

Oi, Aussies! I’ll be at the AIFST conference in Melbourne next week (not presenting, just attending). Hope to see you there.

Biofilms Masterclass

Sustainability for Laboratories

Why Daily Harvest Used Toxic Ingredients

Carbon Offsetting Explainer - includes a video that is definitely NSFW! (Not Safe for Work)

Not-boring food safety news and resources

Food fraud incidents, updates and emerging issues

Hello,

Welcome to Issue 96 of The Rotten Apple, where I talk about smelly slime, sustainability and toxic protein powders.

Can I just say a huge thank you to everyone who has upgraded to a paying subscriber recently? Thank you for your 💚 💲support💲 💚. We now accept payments in £GBP, €EUR, $AUD and $CAD as well as USD.

If you haven’t dropped a comment in my suggestion box, it’s not too late. I would love to hear what you would like more of (and less of), and whether you would want to hear from me more than once per week.

I’ve got a great issue for you this week: learn about biofilms, think about the environmental footprint of your lab, discover why a food startup chose to use toxic ingredients (oops) and watch a not-safe-for-work video about carbon offsetting.

As always, food fraud news is at the end for paying subscribers (who are awesome!), including an unusual fraud in bulk fresh grapes, plus updates about potential future risks in soy, coffee and truffles.

Enjoy.

Karen

P.S. If you like this newsletter, please share it with your network. Shares really help me to keep this newsletter growing and thriving.

Biofilms: an Introduction

A biofilm is a complex ecosystem of microorganisms surrounded by slime that was made by those organisms. Or, to put it another way, a biofilm is an “exopolysaccharide matrix embedded with the component cells”.

If you have ever seen a ring of slime around a drain, pinkish-coloured goo on shower tiles or tooth plaque, then you have experienced a biofilm.

The opposite of biofilms is planktonic (free-floating) microorganisms.

Microorganisms within a biofilm exhibit different behaviours than planktonic microorganisms. Biofilms have intercellular signalling systems which allow bacteria to sense when they are part of a newly forming biofilm (‘quorum sensing’) so they can produce specific messenger chemicals to regulate slime (‘extracellular polysaccharide’) production and assemble scaffold proteins that create the structure of biofilm.

How do biofilms form?

Biofilms form in a four-stage process. First, the material to which the biofilm will attach (the ‘substrate’) is conditioned for attachment. Conditioning occurs when dissolved organic matter from the water on the surface of the substrate adsorbs to the substrate. This gives the bacteria a ‘foothold’ to attach to the surface.

The next stage of biofilm formation is the reversible binding of bacteria to the surface. Thirdly, the binding becomes irreversible and microcolonies of organisms begin to form. Finally, the complex structure of the biofilm develops in three dimensions, containing a complex ecosystem of microorganisms (source).

The physical structure of a biofilm, with layers of slimy polysaccharides, provides protection to the microorganisms inside it. This makes biofilms significantly more resistant to cleaning and disinfecting than planktonic microorganisms.

Biofilms in the food industry

Biofilms can be both harmful and beneficial in the food industry. Harmful biofilms contain pathogens and food spoilage organisms, while beneficial biofilms contribute to food fermentation processes and wastewater treatment.

Biofilms can form on surfaces in food handling areas and become an environmental source of contamination.

Biofilm buildups cause fouling in heat exchangers, water pipes, cooling towers and filtration systems which reduces their efficiency.

Biofilms on metal surfaces can promote and enhance corrosion.

Plus, they smell bad!

How do you get rid of biofilms?

The best way to manage unwanted biofilms is to keep surfaces clean and dry, so that biofilms cannot form.

This is why food safety auditors hate to see puddles of standing water in food factories; they are the perfect place for biofilms to form.

If a biofilm does develop it must be removed using physical means - chemical agents are not effective against biofilms. Brushing and scrubbing will break the structure of the biofilm and release it from the surface allowing it to be removed completely so the surface can be cleaned and sanitised.

High-pressure washing is not recommended as it can disperse microorganisms from the biofilm onto food and food contact surfaces.

Other methods discussed in academic literature include ultrasound and electric fields; magnetic fields and metallic nanoparticles as well as biological cleaning agents containing bacteriocins and bacteriophages.

Cleaning agents that contain enzymes to break down the extracellular matrix in biofilms can be used in conjunction with other methods. Heat, hot water and steam are often used after the matrix has been broken down.

Learn more about biofilms

Here are some peer-reviewed sources with more information about the formation and control of biofilms:

🍏 Biofilm formation and control strategies of foodborne pathogens: food safety perspectives

🍏 Biofilms in the Food Industry: Health Aspects and Control Methods

🍏 Significance of microbial biofilms in food industry: a review

Sustainable Laboratories

Laboratories are a crucial part of food infrastructure. Food labs range from on-site labs which perform quality tests during food production to high tech research laboratories where cutting-edge discoveries are made and new analytical methods are pioneered.

When it comes to sustainability, scientific laboratories are crucial for finding ways to make the food industry more sustainable. At the same time, laboratories are relatively heavy polluters, for the size of their operations. For example, laboratories use significantly more energy and water than equivalent-sized office buildings and generate significant quantities of plastic waste.

Environmental Impacts of Laboratories

Median energy usage of a laboratory is about three times higher than a similar sized office.

Laboratory buildings are responsible for 60% of Oxford University’s total energy consumption and carbon emissions.

Fume hoods and ultra-low temperature freezers are the most energy intensive equipment types in ‘typical’ laboratories, with ultra-low temperature freezers using as much energy as an average household every day and biosafety cabinets using 15 kWh/day – about half as much as a household.

Water usage is high for many labs, with more than 60% of water usage by one University occurring in laboratory buildings (source).

Chemicals used in laboratories can be polluting or have a large carbon footprint, or both, with many solvents derived from fossil fuels.

Single-use plastics are commonly used in laboratories, particularly those that require sterile elements, such as food microbiology labs. Plastics in labs include pipette tips, tubes, flasks, vials, sample bottles, syringes, gloves, well plates, test kits, cups, masks and packaging.

Reducing the environmental impact of laboratories – what others are doing

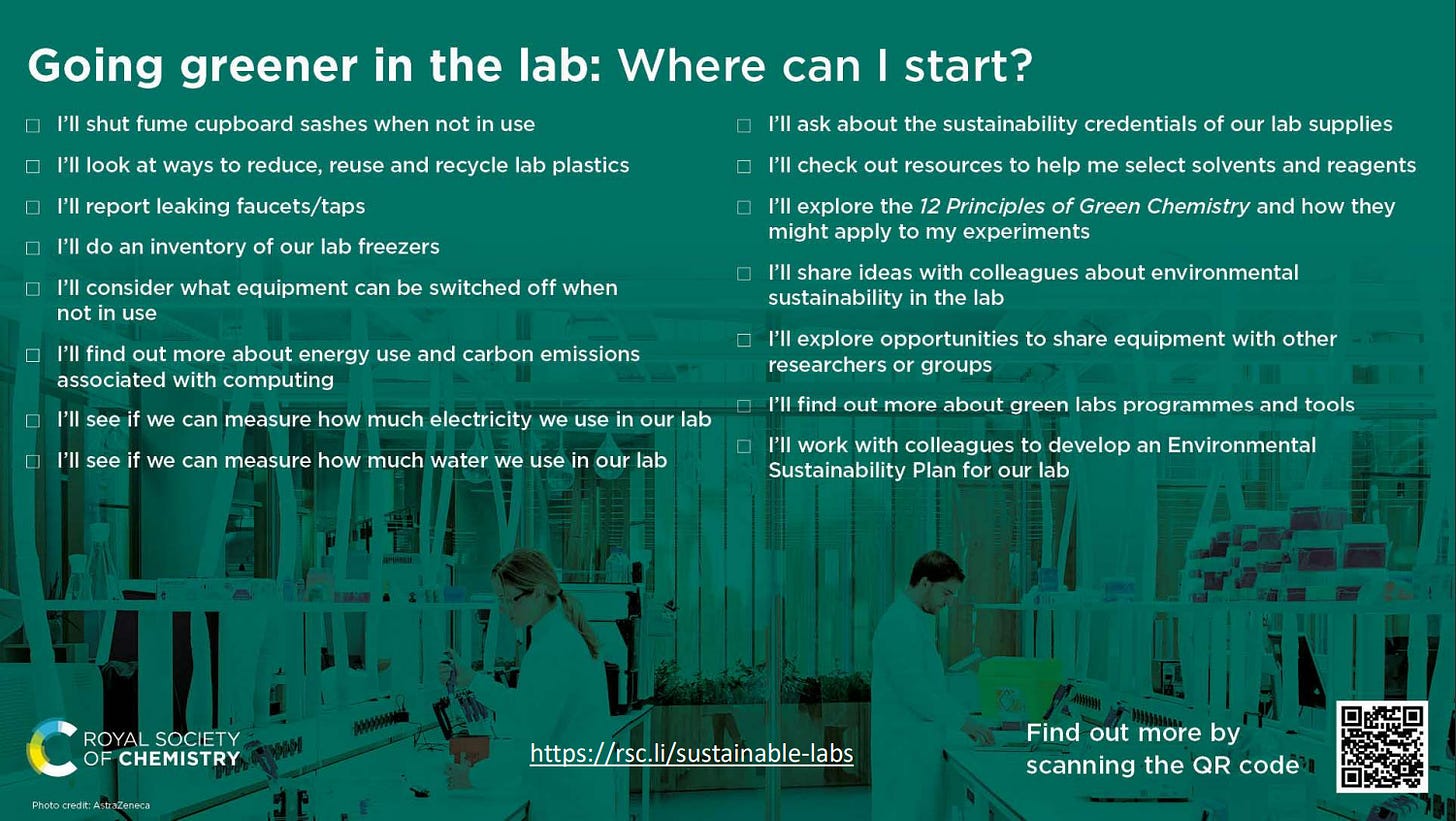

A survey by the (UK) Royal Society of Chemists (2021) found that many scientists were taking small steps to reduce the environmental impact of their labs, although larger changes like finding alternative suppliers and switching equipment were considered much more difficult.

79% of respondents were switching off equipment when not in use to save energy;

75% of respondents were closing fume hoods to reduce energy consumption (keeping sashes closed can save up to 40% of energy)

41% were reducing water consumption by, for example, using waterless condensers.

Only 19% of respondents considered the energy consumption of equipment during decision making and only 34% were purchasing more energy efficient models of equipment.

What will you do?

Consult the infographic below for a list of ideas about how to go greener in the lab.

Food Safety News and Resources

No ads, no sponsored content: our weekly roundup of global food safety news is carefully curated and only top-quality information makes the cut.

This week’s news includes deadly protein powder, histamine poisoning and dangerous truffles. Click the preview below to access it.

News and Resources Roundup

17th July | Food Safety News and Free Resources | ⚠ 💀 Potentially fatal levels of caffeine in protein powder (UK) 💀 ⚠ Protein powder that contains extremely high levels of caffeine has been subject to a recall in the United Kingdom. The levels of caffeine could be fatal. 13/07/2023

How a Direct-to-Consumer Food Company Ended up with Toxic Ingredients in Its ‘Healthy’ Food

The CEO of Daily Harvest explains

Last year, multiple customers of Daily Harvest, which sells sustainably sourced plant-based foods direct to consumers, ended up in hospital, with many requiring surgery. After months of investigations by the company, the US FDA and independent bodies, the illnesses were tentatively attributed to an unusual ingredient in Daily Harvest’s lentil crumbles: tara protein flour.

An interview with the CEO of Daily Harvest, published by Fast Company last month, reveals how the tara flour came to be used in the lentil crumbles recipe, despite containing chemicals that are potentially toxic to some consumers.

The interview provides interesting insights into food product development in smaller, ‘nimble’ startups and reveals huge regulatory gaps in USA food commerce.

In the interview, the CEO reveals that Daily Harvest was trying to find high-protein, plant-based ingredients that did not contain common human food allergens. That meant no wheat, soy or nut-based protein sources and left few traditional plant-based options for a new protein-rich meal-topper ‘crumble’.

Tara protein flour, with its high protein content, seemed like a good option.

Daily Harvest’s staff did perform some due diligence before deciding to use it in their products. They checked with the tara supplier, which “positioned” the ingredient as GRAS (generally recognised as safe).

In addition, at least one person associated with the supply chain claimed that the flour was safely consumed by indigenous Peruvians as a staple part of their diets, a claim that other experts have since been unable to verify.

In the USA, it is acceptable for an ingredient seller to make their own self-declaration of GRAS status.

Daily Harvest’s staff did not imagine that the tara protein flour was a novel ingredient because it was positioned by the supplier as widely used. Their CEO told Fast Company “There were multiple established reputable suppliers in the U.S. that had it [tara flour] in their catalog. In hindsight, we learned that while it was offered by many [suppliers], it’s unclear how much it had actually been used.”

Over the past decade, multiple commentators have expressed their concerns that startup food companies don’t have enough food safety expertise to prevent these types of food safety disasters, including nutritionist and public health advocate Marion Nestle who says “This has been a scandal for decades”.

Daily Harvest says they have changed their sourcing procedures.

Meanwhile, many of the 133 consumers who were hospitalised after eating the recalled food are still struggling with daily health issues.

Read our coverage of the Daily Harvest Tara Flour saga in past issues:

🍏 For more on this story see Issue #44, Issue #46, Issue #64 and Issue #92 🍏

Carbon Offsetting Explained

Featuring a *not safe for work* video

Carbon offsetting is a widely used but controversial way for large greenhouse gas emitters to claim they are reducing their carbon footprints. Carbon offsetting is the process of contributing to projects that are claimed to reduce atmospheric carbon dioxide, such as planting forests.

Independent investigations have shown many carbon offsetting schemes to be completely worthless, containing ‘phantom’ credits, contributing no genuine carbon reductions and perhaps even making global warming worse.

“Respect the PowerPoint” says the carbon offsetter in the video below as he showcases his new initiative in Venezuela.

Warning: This 2 minute video is not safe for work

Tiktok failed to load.

Tiktok failed to load.Enable 3rd party cookies or use another browser

(If the preview is not displaying for you, try this link)

What you missed in last week’s email

· AI in Food Systems - actual examples, without the hype

· How isotopes are used in food testing

· News and Resources Roundup (food safety news without the boring bits)

· The food fraud academic paper that made me 🤔🤨😐

· Food fraud news, incidents and updates, including Salmonella-contaminated counterfeits of famous brand spices

Below for paying subscribers: Food fraud news, incident reports, and emerging issues, plus 🎧 an audio version 🎧 so you can catch up while on the go

📌 Food Fraud News 📌

Tuna fraud that caused histamine poisoning and sickened dozens of people in 2021 has been investigated and suspects have been subject to court orders, detention and house arrest. The fraud allegedly involved defrosting yellowfin tuna; adulterating it with