225 | Top 5 NCs | 6 Parmesan Facts |

+ Chemistry avocados

This is The Rotten Apple, an inside view on food fraud and food safety for professionals, policy-makers and purveyors. Subscribe for insights, latest news and emerging trends straight to your inbox each Monday.

Food fraud talks

Cheese time: Parmesan in the spotlight

Top 5 Non-conformances from BRCGS

Avocado’s number

Food fraud news with crispy snails and no-milk milk

Welcome to another week of food safety + food fraud goodness.

Thank you for trusting me with your time and making space in your inbox for me each week. I love you all*!

Welcome to Issue 225, where I unpack the BRCGS’s top non-conformances of 2024-2025 and delve into the beautifully stinky world of the world’s most famous hard cheese.

As always, food fraud news is at the end, with horizon scanning, recent incidents, methods, a fantastic turmeric report and an invitation to a conference in Dublin.

Have a fabulous week.

Karen

P.S. *I especially love those of you who support my work financially 👏 Huge shoutout to Angela and John from the UK, Frank from Germany, lging from the US, Debbie from South Africa and Nina from Australia ,for upgrading your subscriptions 👏 I couldn’t do this without you. Thank you ♥

Food Fraud Talks

The first session of Food Fraud Talks was held last Tuesday and I thoroughly enjoyed discussing trends in food fraud with Ms Solmaz-Kaiser of iComplai. We plan to hold these food fraud talks once per quarter in 2026.

Click the image below to watch a replay.

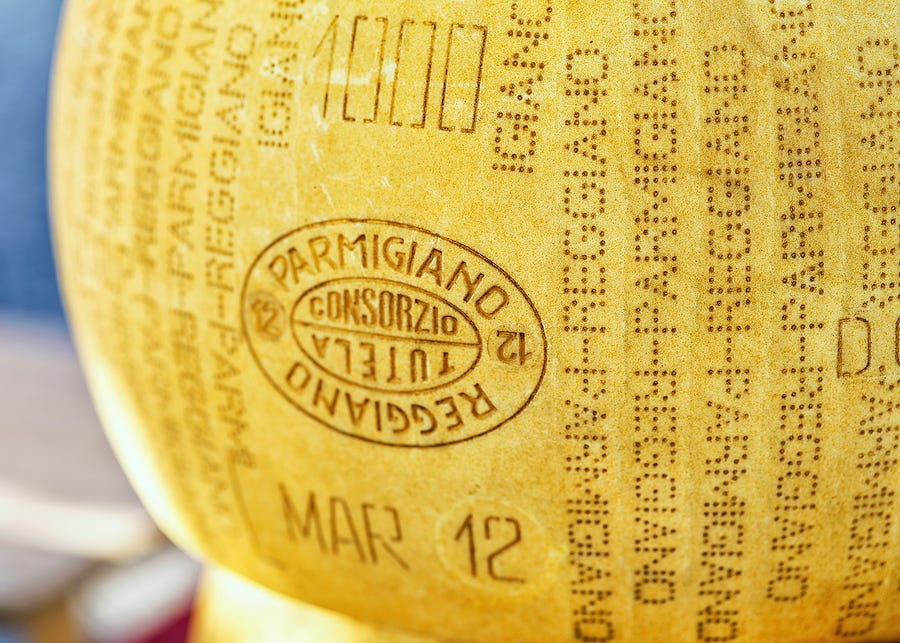

Cheese time: Parmesan in the spotlight

Mmmmm yum! Parmigiano Reggiano is an Italian cheese with a complex, intense, nutty flavour, and a distinctive granular, crumbly texture.

It originated in medieval Benedictine and Cistercian monasteries, where monks developed a hard cheese that would keep for long periods. Today, it is still produced in the Emilia‑Romagna region of northern Italy using traditional methods that closely resemble those used centuries ago.

It’s known as Parmesan cheese in some places, but is absolutely not equivalent to ‘parmesan’ in other parts of the world.

Parmigiano Reggiano is a legally protected name under the European Protected Designation of Origin (PDO) system. There are strict rules about where and how it’s made and what ingredients are used.

Parmesan is a legally recognised translation of Parmigiano Reggiano in Europe, so in Europe and the United Kingdom, cheese may only be called ‘parmesan’ if it meets the PDO definition of Parmigiano Reggiano. However, ‘parmesan’ is used to describe other hard cheeses in other parts of the world, including the US, Canada and Australia.

Producers and institutions in Italy are furious that non‑Italian cheeses are called ‘parmesan’ because the use of the name exploits the reputation of Parmigiano Reggiano without meeting the same standards. They’ve fought and won legal cases in Europe to stop ‘parmesan’ being used on imitations, and they lobby internationally on this point.

True Parmesan cheese - Parmigiano reggiano - must be made in northern Italy’s designated zone, using only raw cow’s milk, salt and rennet. The milk used must come from cows raised in the designated production zone, and the cows must be fed primarily on forage sourced from that same area.

Reminder: Cheese-making: The process usually starts with fresh milk, which is (often) pasteurised and then inoculated with starter cultures that acidify the milk and develop flavour. A coagulant, commonly rennet, is added to cause the milk proteins (casein) to clump together, forming curds.

The curds are cut to release whey and then heated, stirred and drained. The degree of cutting and heating determine the cheese’s texture. Salt is added for flavour and preservation. The curds are then pressed into solid form. As the cheese ages, enzymes and microorganisms break down proteins and fats to give the distinctive textures and flavours characteristic of different varieties.

Did you know? Wheels of Parmigiano Reggiano may be used as collateral for a bank loan in the Emilia-Romagna region of Italy. Each wheel is worth up to USD3,000. The bank stores and ages them in climate-controlled vaults for the duration of the loan (source).

Food fraud in ‘parmesan’ and Parmigiano Reggiano

Parmigiano Reggiano gained protected designation of origin (PDO) status in 1966, but increasing demand for the cheese, and its high price, have made it vulnerable to food fraud.

The Parmigiano Reggiano Consortium – an oversight body in Italy that certifies cheese authenticity – estimates that the global turnover of counterfeit parmesan is around US$2bn – almost as much as the value of genuine cheese. Parmigiano Reggiano is also the target of theft and has its own black market.

In 2023, the Consortium launched a three-year campaign to educate both trade and consumer audiences.

Producers are also fighting back against counterfeit products by inserting microtransponders about the size of a grain of salt into the hard rinds of Parmigiano Reggiano cheeses.

The microchip contains a unique code that can be scanned to verify the authenticity of the cheese. It also contains information about the cheese’s production, such as the date, location, and producer.

The microchips are long-lasting, virtually impossible to counterfeit, and can withstand solvents and reagents. They are also food safe, though their location in the rind makes them unlikely to be eaten.

Six things to know about Parmigiano Reggiano

The bacteria that guarantee the specific characteristics of Parmigiano Reggiano only grow on the grass within the defined geographical area.

Leftovers (whey) are used to feed pigs for making Parma ham.

Each wheel of genuine Parmigiano Reggiano must weigh at least 30 kg, but many are 40–45 kg. And it takes around 575 L of milk to make one wheel!

Wheels of cheese are aged (kept on shelves) for at least 12 months (but usually 24 months and sometimes for 40 months or more) before they can be sold.

The tiny crystals you see in the grain of properly aged Parmigiano Reggiano are not salt, but tyrosine, an amino acid that comes from the milk casein as it breaks down. Older cheeses have more crystals.

More finely cut curd leads to fine granular textures in the finished cheese. For Parmigiano Reggiano, the curd is cut into pieces the size of a grain of rice, which gives the finished cheese a fine granular texture. Creamier, moister cheeses are made with larger pieces of curd.

Main source (others are linked inline):

Southey, F (2023). Inside the dairy: How is ‘king of cheeses’ Parmigiano Reggiano made’, Food Navigator. Available online: https://www.foodnavigator.com/Article/2023/05/22/How-is-Parmigiano-Reggiano-made-We-take-a-look-inside-the-dairy/.

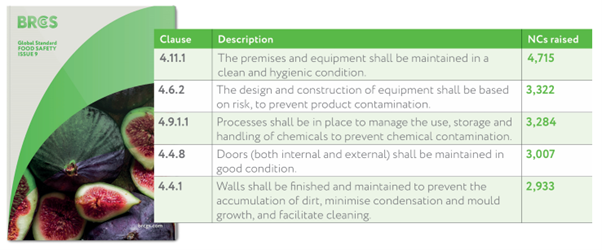

Top 5 Non-conformances from BRCGS

Non-conformances are formally recorded instances of a gap between practice and the requirements of relevant standards, regulatory obligations, or approved internal procedures.

The food standards owner BRCGS (Brand Reputation through Compliance Global Standards) recently published an overview of non-conformances recorded during audits to their 5 major standards in 2024 and 2025: BRCGS Food Safety, Packaging Materials, Storage and Distribution, Global Standard for Agents and Brokers and Global Standard Consumer Products – General Merchandise.

Here’s a breakdown plus key takeaways for avoiding non-conformances.

BRCGS Food Safety

There were more than 17,000 non-conformances (NCs) issued in audits against the food standard, and 47% them were related to hygiene and cleanliness. The top NC, accounting for 27% of all NCs, was against clause 4.11.1 “The premises and equipment shall be maintained in a clean and hygienic condition” and the second most common NC (19%) was also hygiene-related, specifically for not having hygienically designed equipment (clause 4.6.2 “The design and construction of equipment shall be based on risk, to prevent product contamination”). Together, these two clauses accounted for almost half of all NCs awarded during the two year peiod.

Chemical handling system deficiencies accounted for a further 19% of NCs, followed by the condition of doors (clause 4.4.8) and walls (clause 4.4.1) at 17% each.

These top 5 non-conformances are similar to those recorded in previous years: hygiene, maintenance, doors, chemical controls and walls were top in 2022.

Comment: I’m not sure what I think about these results. Is it good that more critical clauses did not appear in the top five list – for example, HACCP plan-related clauses - or is it bad that so many facilities are either unclean or uncleanable due to hygienic design and maintenance failures?

Perhaps the NCs awarded to poor-performing businesses are quite varied, with one business doing a terrible job of allergen segregation, another having a disastrous HACCP plan, with the only thing in common being a problem with cleanliness and hygiene. The data doesn’t tell us.

Maybe food safety audit performance is a bit like the happy and unhappy families described by the writer Tolstoy in the opening line of his novel Anna Karenina*: Good food businesses are all alike; every unsafe food business is unsafe in its own way.

*“Happy families are all alike; every unhappy family is unhappy in its own way.” (Tolstoy)

Packaging Materials

When it came to the packaging standard, the clear winner in NCs for 2024-2025 was related to poor housekeeping, followed by temporary repairs using “cardboard, tape, etc.”, chemical handling and storage and pest control, with the physical condition of facilities coming in a distant fifth.

Storage and Distribution

Audits against the Storage and Distribution standard had two stand-out NCs: Pest proofing failures and cleanliness of premises and equipment.

Maintenance of walls, floors and ceilings and problems with physical contamination controls were the third and fourth most common sources of NCs.

The fifth most prevalent NC for storage and distribution businesses was against the clause requiring them to have a system in place to identify customer requirements (clause 3.2.1 “A system shall be in place for identifying whether customers have specific requirements.”). Surely that’s a key component of any professional S&D operation?

Global Standard for Agents and Brokers

Audits against the Agents and Brokers standard didn’t deliver a standout area of non-conformance. That is, the top 5 NCs for this standard were similarly prevalent.

The most common NC, by a small margin, was for food safety culture deficiencies (Clause 1.1.2 “Defining and maintaining a product safety and quality culture within the company”), followed by failures with hazard analysis, internal audit scheduling, document control and the absence of flow diagrams.

Consumer Products - General Merchandise

For audits against the Consumer Products - General Merchandise standard, the most prevalent NCs were for cleanliness of facilities, followed by physical contamination controls (e.g. glass register) and pest control.

How to avoid common non-conformances

Follow the tips below to avoid the non-conformances listed above.

Have a fresh set of eyes inspect your facility for hygiene issues related to the design, construction and maintenance of premises and equipment. This could be an expert from a sister site or an external consultant. The document Hygienic Design Principles, by EHEDG provides excellent (free) guidance.

Inspect all external doors from the inside. If you can see daylight around the edges, or if there is any gap wider than a pencil, then pest-proofing is needed. Ask your pest contractor to install it.

Keep doors closed to exclude pests, dust, birds and other sources of contamination.

Use a new or different internal auditor or external consultant to check your chemical control systems against the requirements of the standard, making sure each part of each clause is adequately addressed.

Check that pest responsibilities are defined, and that pest contractors’ activities adequately address all the requirements of your standard.

Key takeaways

Non-conformities related to hygiene and cleanliness dominated in audits against BRCGS standards, with hygiene-related NCs making up almost half of the 17,000 NCs awarded in audits against the food safety standard in 2024 and 2025.

Housekeeping was the most common problem in packaging facilities, and culture was the top problem for brokers and agents. For storage and distribution centres, pest proofing and cleanliness were the most common issues.

If you’ve got an audit coming up, or an unannounced audit looming, review your facility and equipment cleanliness and cleanability and ensure all walls and doors are properly maintained, easy to clean, pest-proof and operating correctly at all times.

And remember that the main aim of passing audits and avoiding non-conformances is to have a robust and well-implemented food safety program to protect your customers and consumers.

Passing a food safety audit is not about obtaining a certificate or a gold star – it is about establishing a sound food safety program in your facility to protect your brand, your buyer, and your bottom line. [modified from] The Safe Food Quality Institute

Source: BRCGS (2026) BRCGS Annual Report 2024-25. Available online: https://www.brcgs.com/media/zqxnctso/brcgsannualreport2024-25-screen.pdf

Avocado’s number (just for fun)

Who remembers their chemistry classes? Me, I remember Prof Bishop, who had such terrible body odour we would physically cringe out of his stink zone as he tried to pass learning materials to us.

Or the time we thought another lecturer was going to ignite a huge bin-liner (trash bag) full of hydrogen at the front of the room….

What I don’t remember is what we did with the Avogadro number. Guacamole perhaps?

If you need a refresher on Avogadro’s number and the mole, here’s a 3 minute explainer.

Below for paying subscribers: Food fraud news, resources and incident reports

📌 Food Fraud News 📌

Authentic Food Festival and Conference

A new event in Dublin will bring together science, industry, regulators, policy makers, and creative thinkers to explore food authenticity, integrity, and fraud on 27-28 May 2026. The event combines conference sessions with interactive labs, debates, films, games, and plenty of opportunities for discussion and networking.

This event is organised by the European Food Fraud Community of Practice (www.eff-cop.eu) and is now OPEN for REGISTRATIONS.

🔹Food fraud incidents from iComplai’s AI-powered food safety and food fraud intelligence platform🔹

🔹 Fake milk powder that consisted of non-dairy creamer mixed with starch, containing mostly maltodextrin with more than 90% carbohydrate and almost no fat or protein, was marketed as “rich in milk, calcium and protein” and suitable for infants and other vulnerable individuals. The milk powder was made to appear as imported milk powder and was sold through e-commerce platforms. The operation was uncovered in 2024 during an investigation into the production of counterfeit foreign-brand milk powder. Three people have been sentenced for their roles in the operation – China 01/12/2025 🔹

🔹 Fake frozen ‘beef’ (250 kg), made by mixing pork, cow’s blood and “industrial chemicals” including industrial-grade sodium metabisulfite and “various additives” was seized after inspectors raided a processing facility where the meat was prepared. The facility had been producing 600 kg of the fake beef daily, with sales to restaurants at around half the usual price of beef – Vietnam 22/12/2025 🔹